Product Description & Characteristics

Bronze, Meehanite®, Graphite

®Meehanite is a trademark of Meehanite Worldwide

- Self-Lubricated Bronze

- Self-Lubricated Meehanite

- Graphite Cradles & Graphite Steel Backed Slide Plates

- Insulated High-Temperature, Low-Friction Assemblies

Self-Lubricated Bronze Bearings

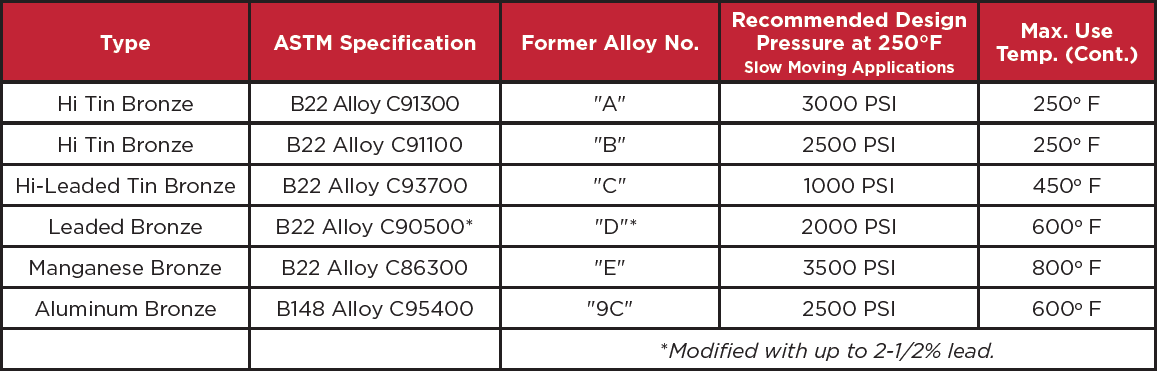

CON-SERV offers slide bearings in a variety of alloys which are approved for nuclear, structural, industrial and bridge applications:

The following information is representative of cast alloys used for expansion bearing plates:

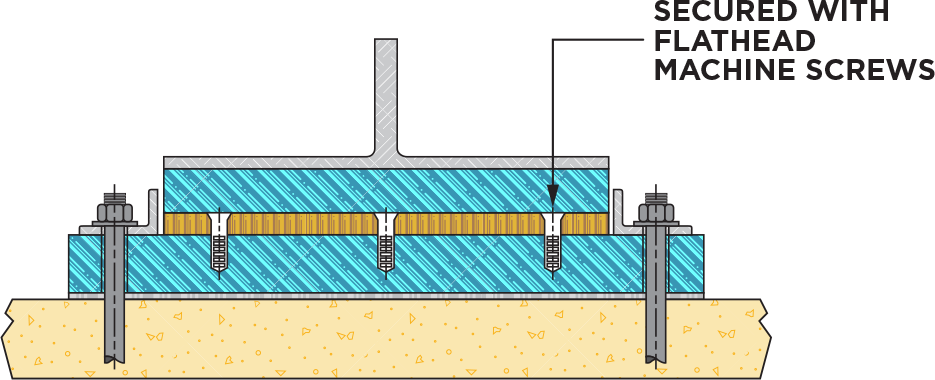

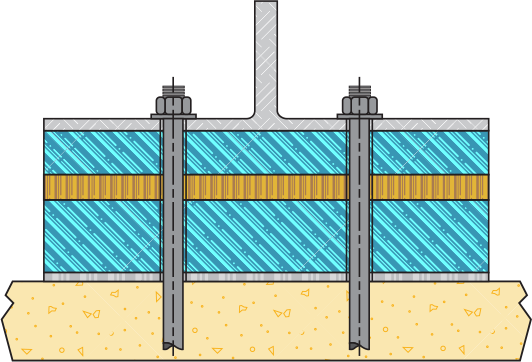

Installation Examples of Bronze & Meehanite

Self-Lubricated Bronze Bearings

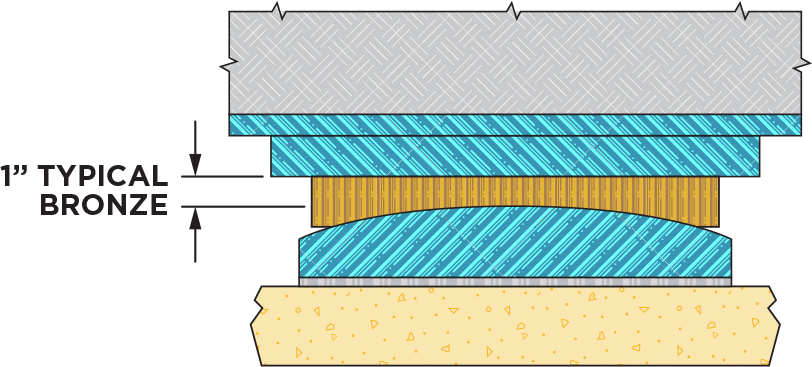

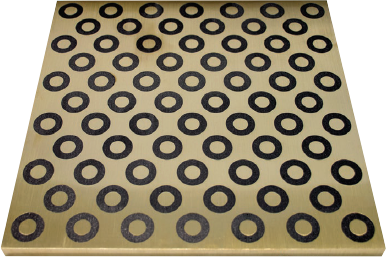

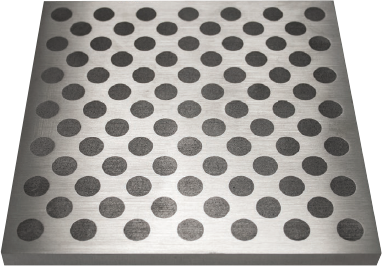

These bronzes are lubricated to approximately 25% of the bearing surface. The standard lubricant takes temperatures up to 250°F. Lube 1 has a temperature range from 250°F to 500°F. Lube 2 has a temperature range from 500°F to 800°F. For nuclear applications (normal containment, atmosphere including borated water spray, and radiation below 2.2 x 106 rads), use Lube AE for all temperatures to 800°F. Slots and holes, if required, shall be fabricated in the bearing manufacturer’s plant.

Designers use 15% friction factor as a practical figure and increase this for high temperature applications (greater than 500°F). Any mating steel surfaces should be finished to a 63 to 125 RMS.

Bronze bearings are cast, machined and lubricated. Edges should be specified “as-cast” or machined.

For alloy C90500 Modified, the maximum design pressure is 800 psi at 600°F. For alloy C86300, the maximum design pressure is 1000 psi at 800°F. A straight-line interpolation is appropriate between the 250°F design pressure and the maximum use temperature pressure.

Hi-Temp Self Lubricated Bronze Bearing

Self-Lubricated Meehanite

Meehanite bearings are generally used for temperatures from 500°F to 1000°F.

This material is a form of gray cast iron which is lubricated with PTFE or graphite. For Meehanite sliding against a ground steel plate (63 to 125 RMS), a design friction factor of 15% is appropriate.

Grade Type GA50 (50,000 Tensile Strength) is usually specified for bearing applications.

For lubricated Meehanite, the following design pressures are appropriate at the respective temperatures:

- 7000 psi @ 500°F

- 5000 psi @ 600°F

- 3000 psi @ 700°F

- 2000 psi @ 800°F

- 1000 psi @ 1000°F

High Temperature Meehanite Bearing

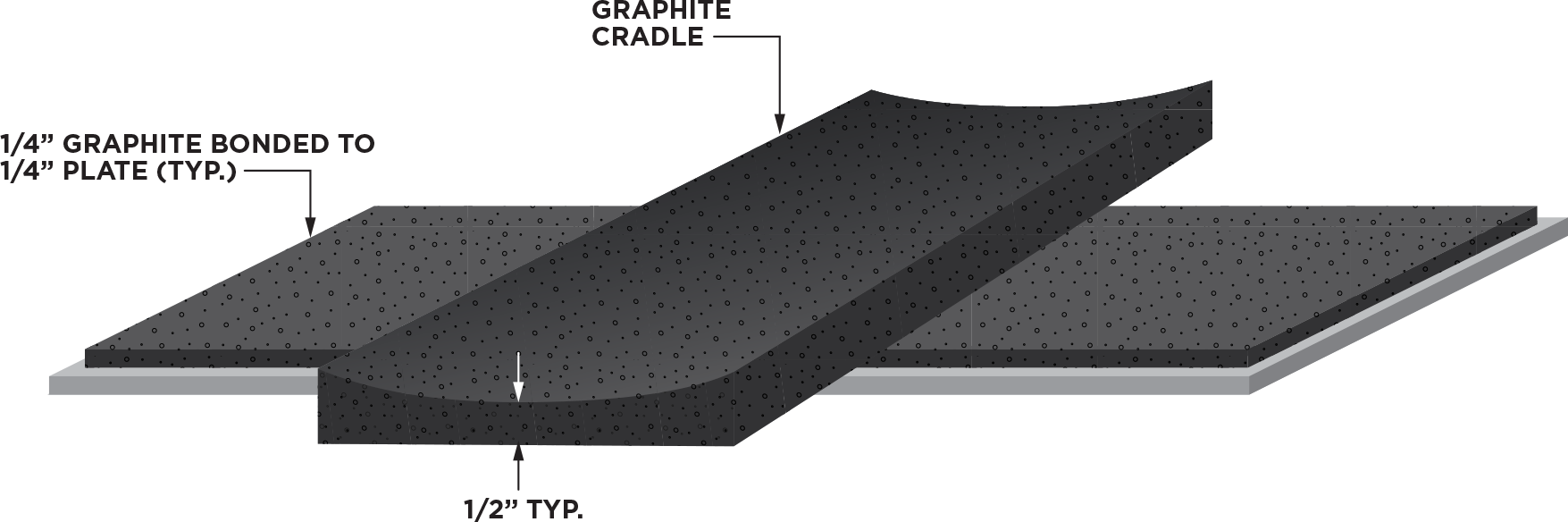

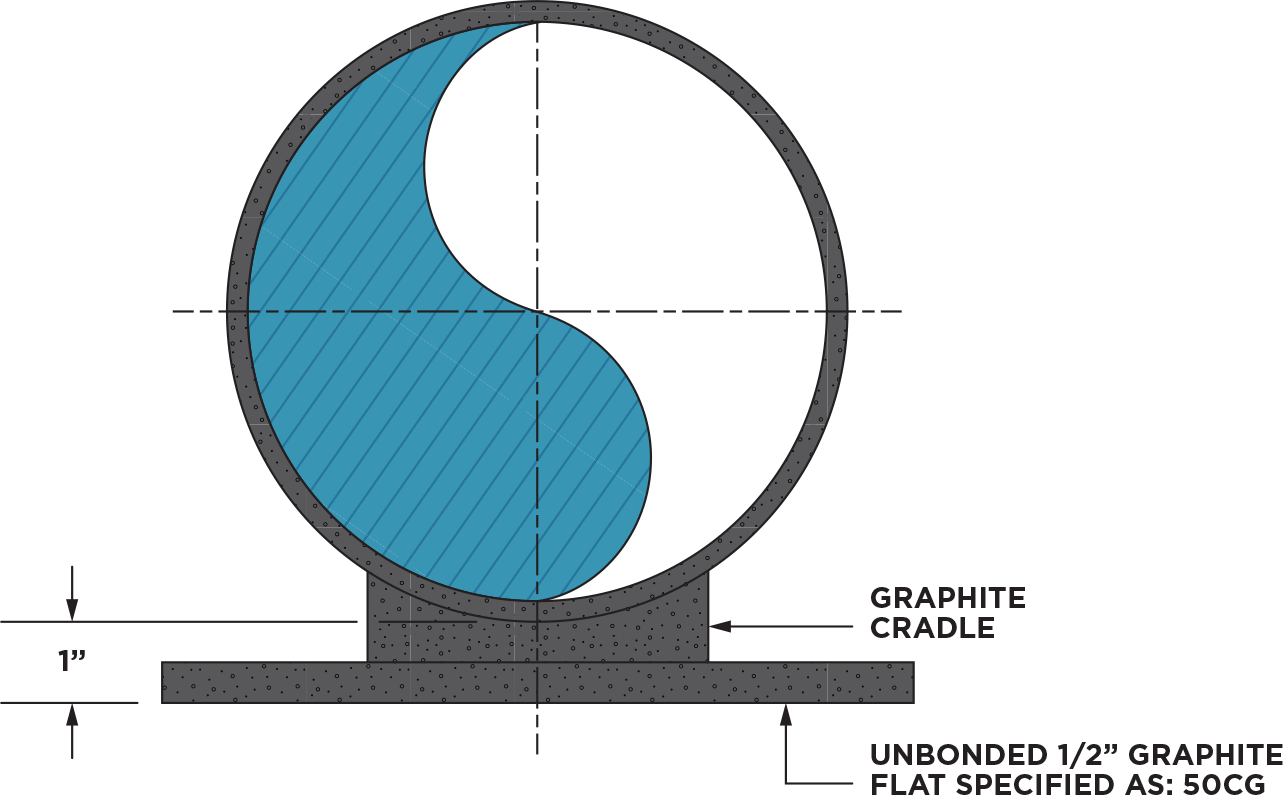

Graphite Cradles & Graphite Steel-Backed Slide Plates

Typical Design Properties:

- Comprehensive Strength: 2000 psi

- Coefficient of friction: Static 0.15

- Maximum Service Temperature: 750° F on graphite

Wear is negligible when sliding against itself. Graphite may be purchased bonded to steel back-up plates or structural shapes as the job may require. Bonding epoxy is available. The maximum temperature limit on the epoxy is 300° F. High temperature applications require mechanical attachment of the graphite. ML written at the end of the bearing callout would signify mechanical locking of graphite – i.e., 25CG 25CS 25L ML.

Unbonded flats are typically ½” thick. Bonded ¼” graphite to ¼” steel is specified as: 25CG 25CS 50L. Typically the steel plate is 1” larger in both width and length than the graphite for field welding.

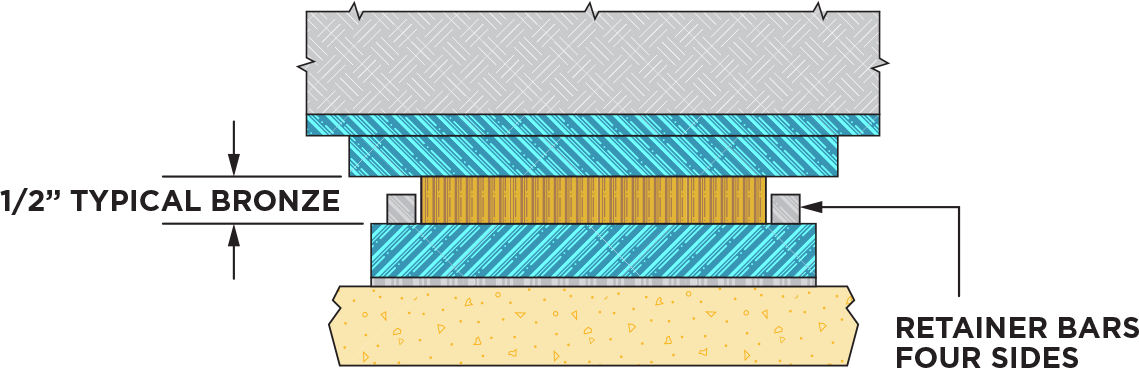

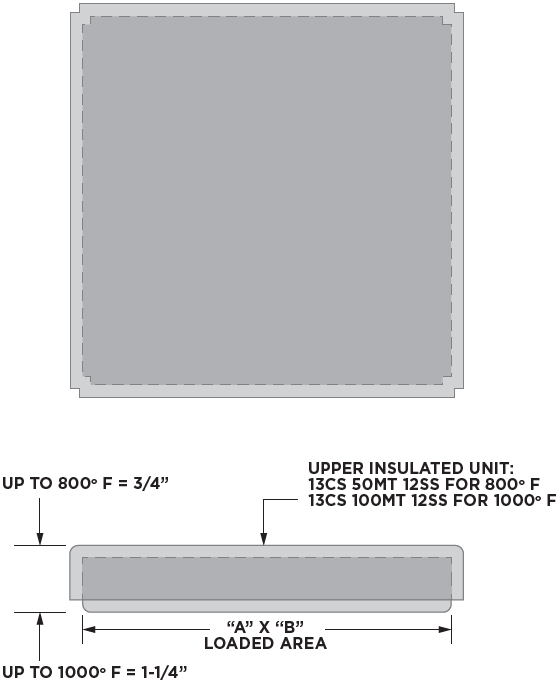

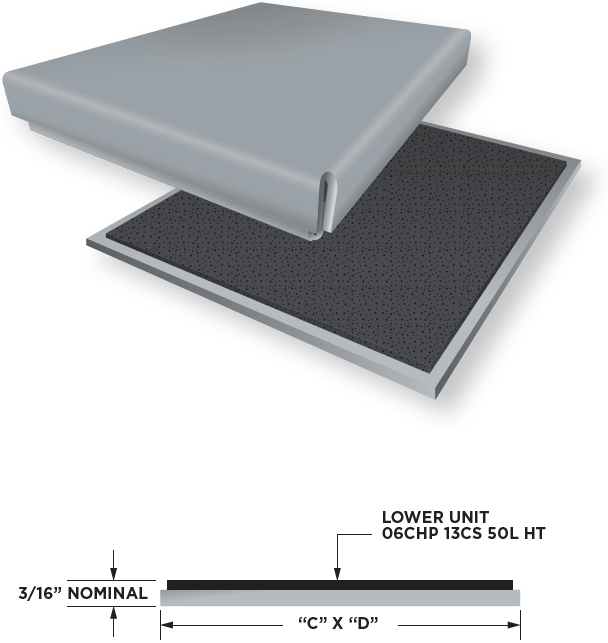

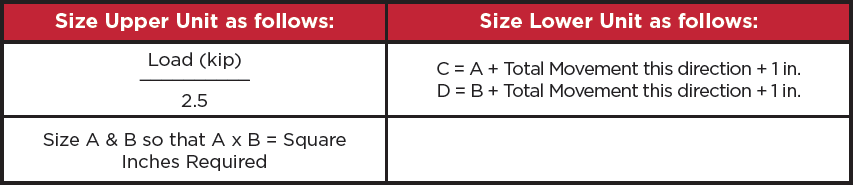

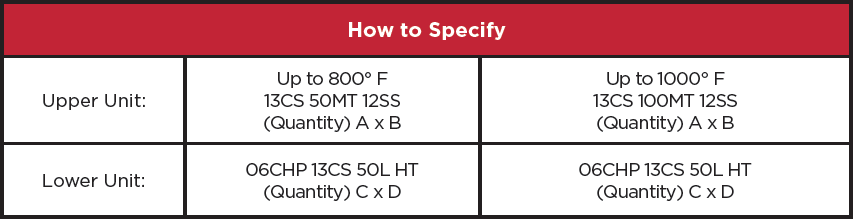

Insulated High-Temperature, Low-Friction Assemblies

Design Parameters

This bearing system enables the designer to enjoy the low friction of PTFE at a bearing point temperature above the use limit (500° F) of PTFE. These bearings provide a coefficient of friction less than 3% at a design pressure of 2500 psi (max.) with little variation at lesser pressures.

The bearings can be installed with a stitch weld ½” long 3” on center on all sides. The upper and lower units must be backed up with structural plates so that a uniform load is transmitted into the unit. Bending of the units is unacceptable.

Alternative materials available: Please consult CON-SERV Engineering Department personnel.