Product Description & Characteristics

CON-SLIDE™ slide bearings are constructed of filled PTFE bonded to flat rigid back-up steel. CON-SLIDE™ slide bearings are designed to reduce friction at loaded expansion and contraction joints in bridges, buildings, pipelines, etc. The CON-SLIDE™ material, at thermal expansion and contraction rates, will exhibit little or no wear for the life of the structure.

CON-SLIDE™ Type CSA (75 psi to 2000 psi)

This blend (CSA) was formulated as a slide material for use against itself.

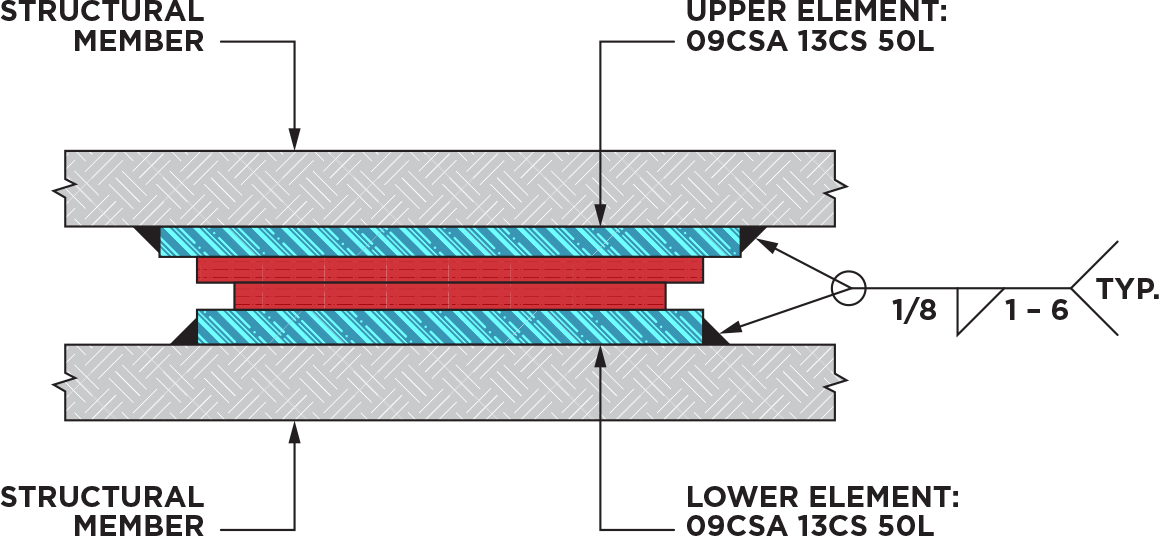

The CSA system consists of an upper and lower element. The PTFE slide surfaces in this system are nominally 3/32” thick and are control-bonded to a 10-gauge carbon steel (CS) back-up sheet. Normally the upper element is larger than the lower element to accommodate the amount of anticipated movement.

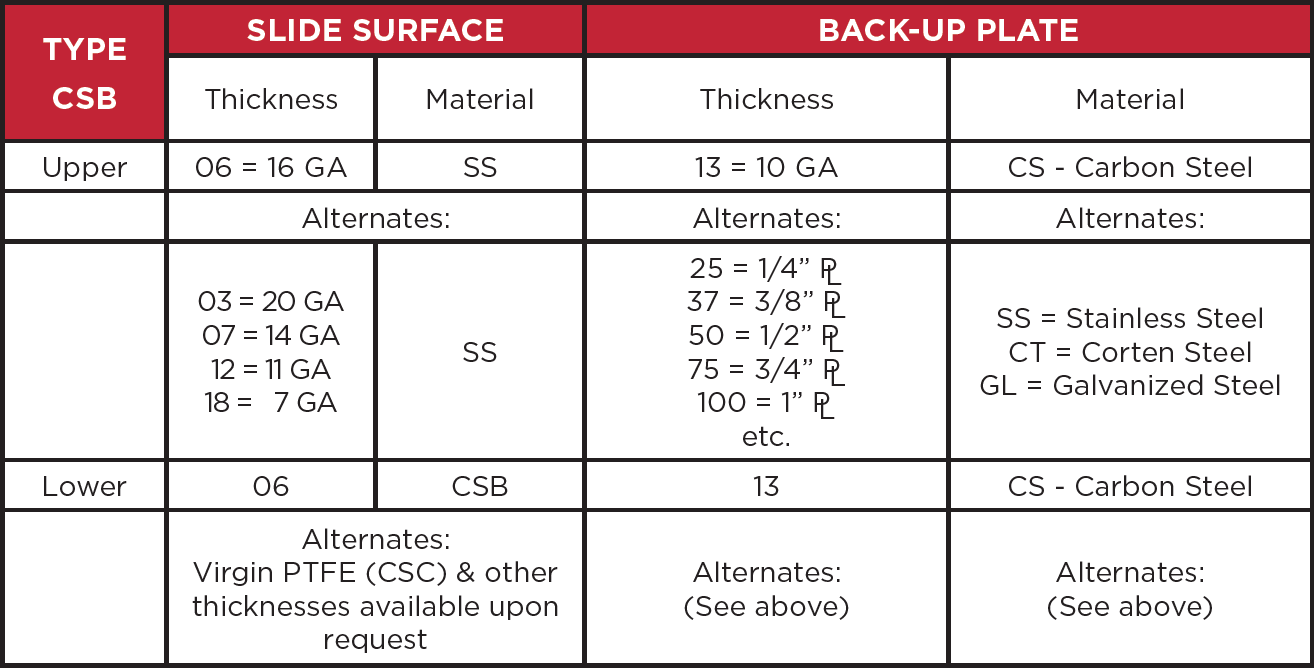

CON-SLIDE™ Type CSB (2000 psi to 4000 psi)

This blend (CSB) was formulated for use as a slide material against a smooth stainless steel surface.

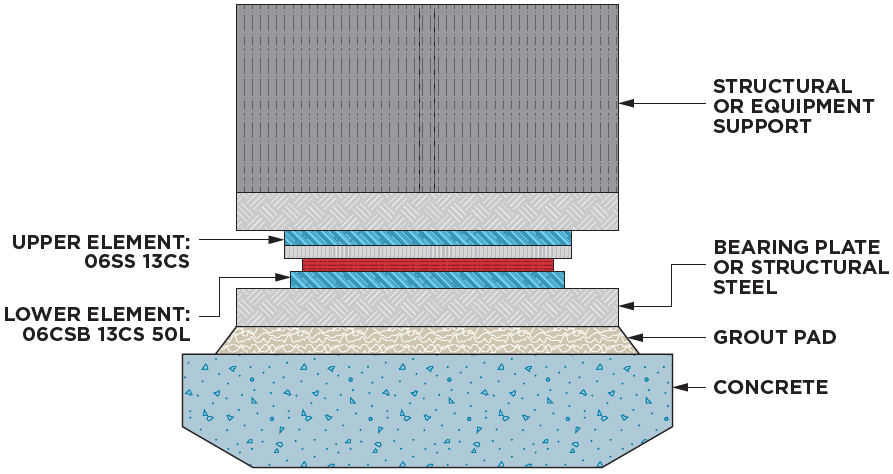

The CSB system consists of an upper and lower element. The PTFE surface is on the smallest element. It is nominally 1/16” thick and is control-bonded to a 10-gauge carbon steel (CS) back-up sheet. The larger element is composed of a 16-gauge stainless steel (SS) sheet, resistance-welded to a 10-gauge carbon steel back-up sheet.

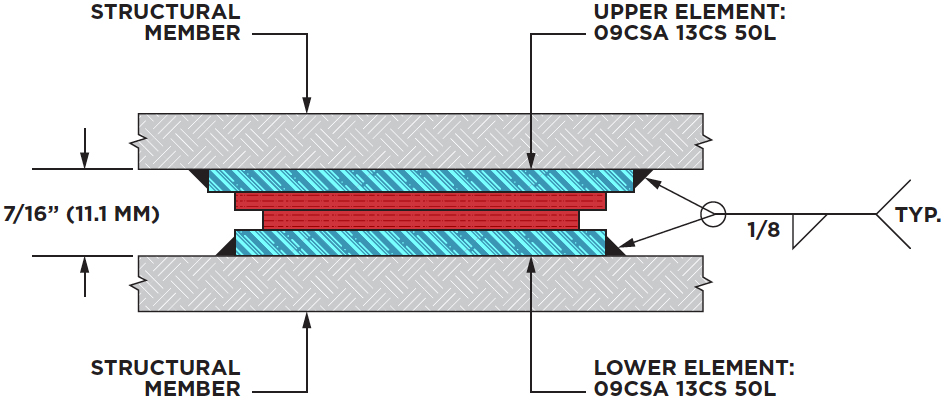

CSA Example

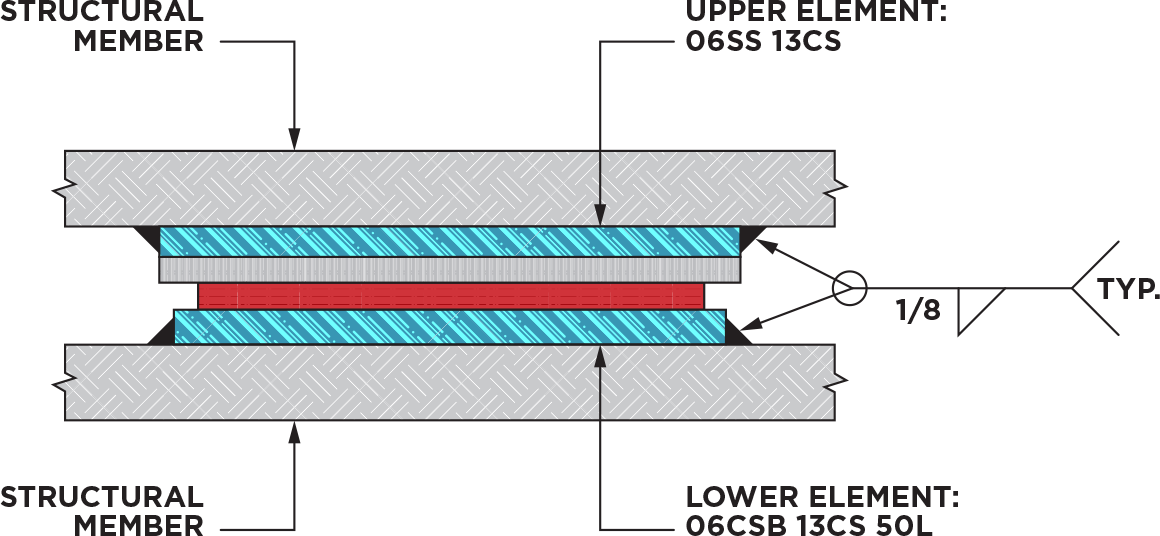

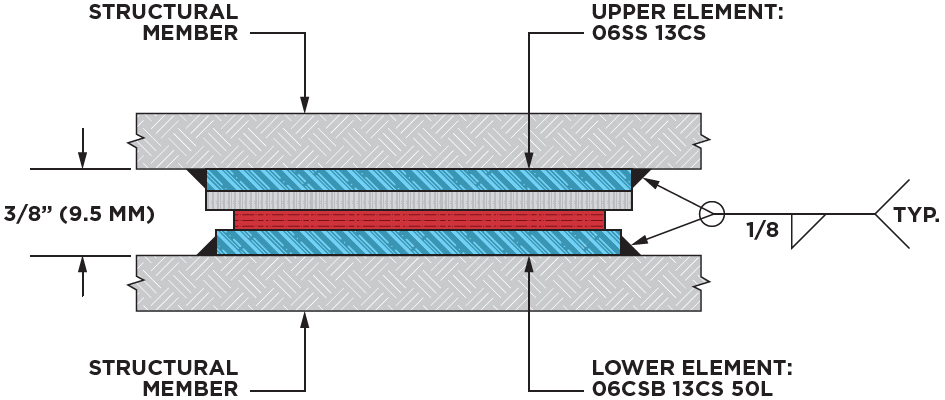

CSB Example

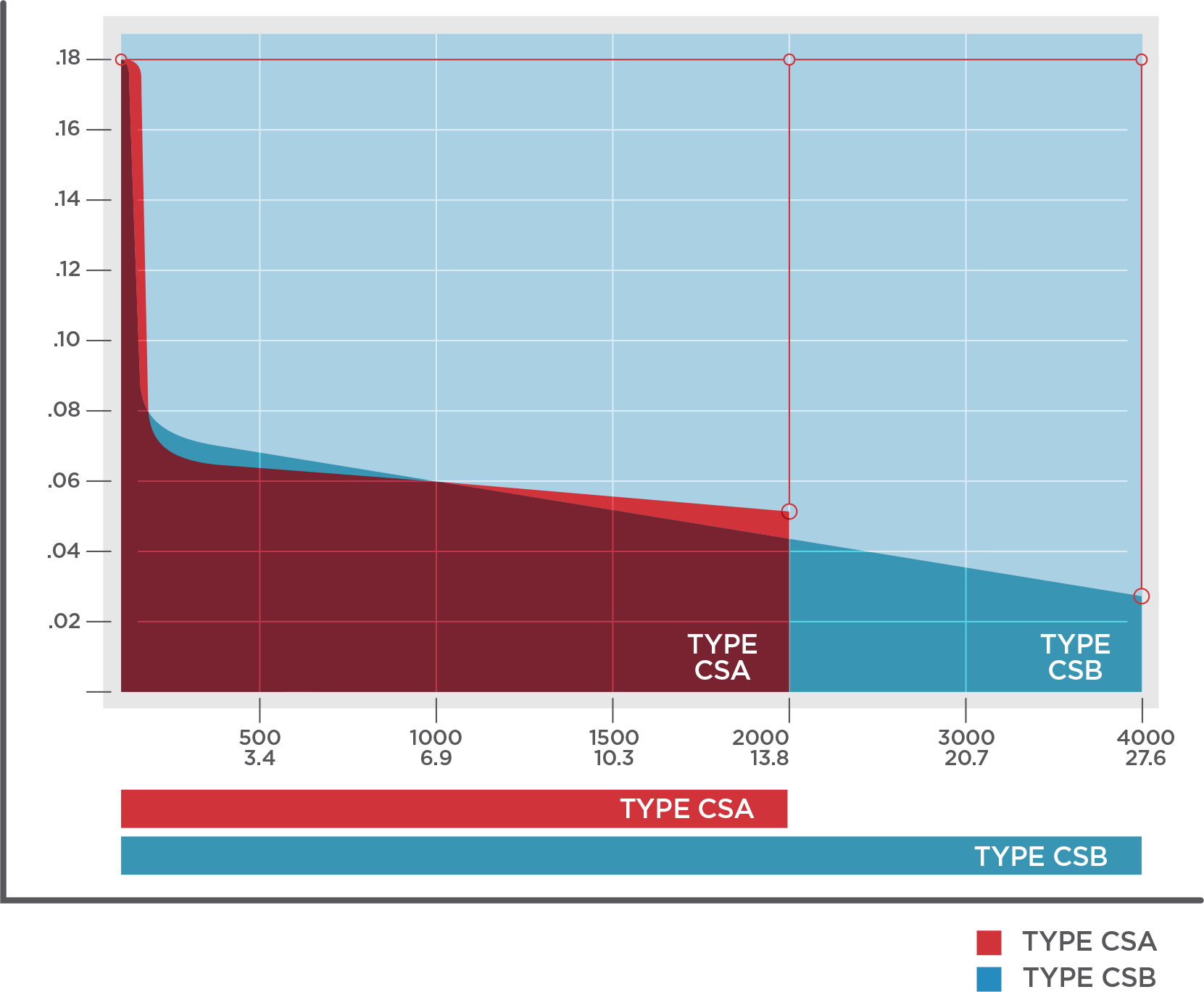

Sizing for Types CSA and CSB

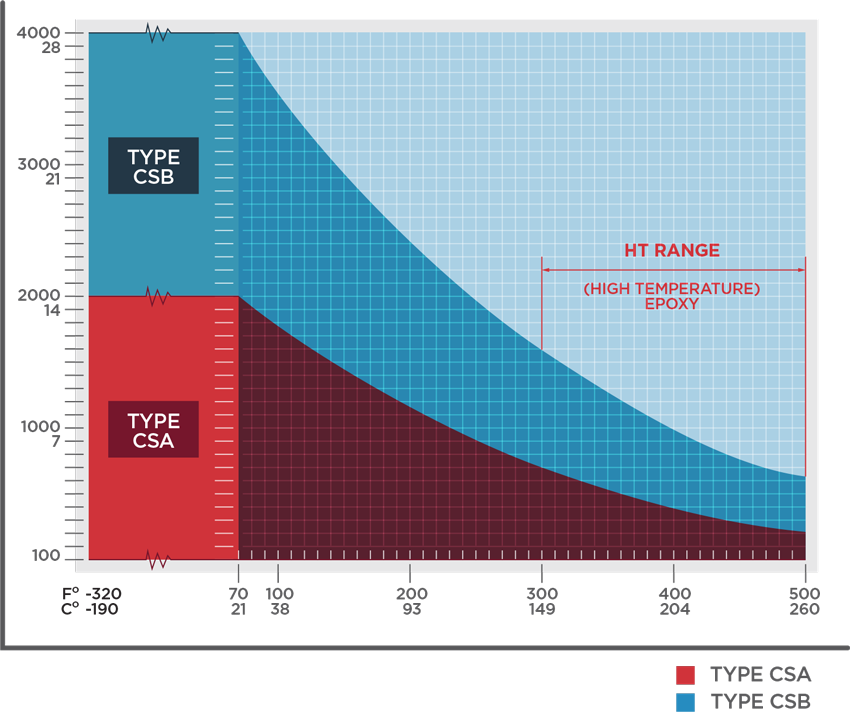

The design engineer shall determine the square inches of bearing area required for the lower element by dividing the load by the allowable pressure indicated in the graph. The upper element is sized for movement after the lower element is sized for load.

CON-SERV can supply any practical element size cut from stock steel. Size is out to out of back-up plate.

For ease of installation, CON-SERV recommends a back-up plate 1” larger than the CSA or CSB to allow a 1/2” recess all around. This recess must be provided for plates requiring a seal weld.

50L = ½” lip all around. If 50L cannot be specified, use a minimum amount of welding to avoid overheating the slide plate. Slide plates smaller than 3” x 3” must have a ½” lip all around for either tack or seal welding.

Alternate Specifiers:

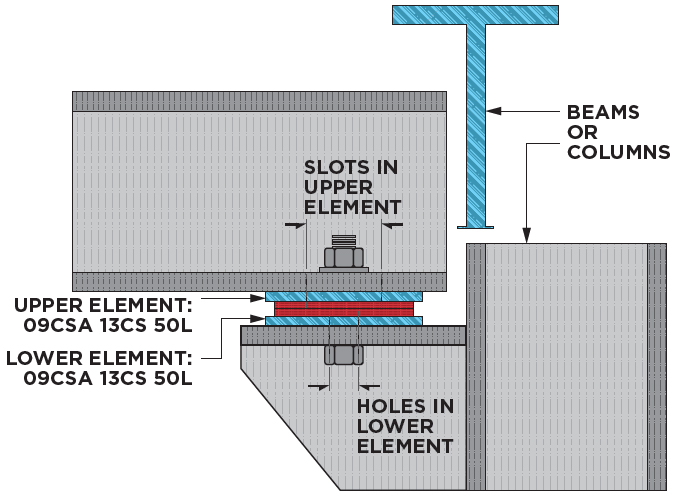

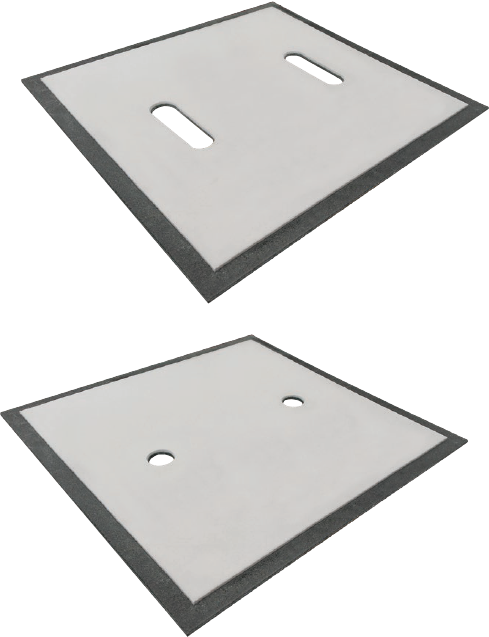

SLOTS & HOLES

If bolts pass through the elements, usually the upper element is slotted for movement; the lower element has holes in it. For example, add two 13/16” x 2” slots in the upper plate and two 13/16” holes in the lower.

STUDS OR ANCHORS

If studs or anchors are welded to the back-up plate, use a back-up plate with a thickness approximately equal to the stud diameter. Add two ¼” diameter x 4” Nelson Studs.

HIGH TEMPERATURE

If the Bearing Point temperature exceeds 300°F, add HT to the call out.

Example: Slots & Holes

Temperature vs. Allowable Load

How to specify Both Types (CSA & CSB)

Standard bearing assemblies examples:

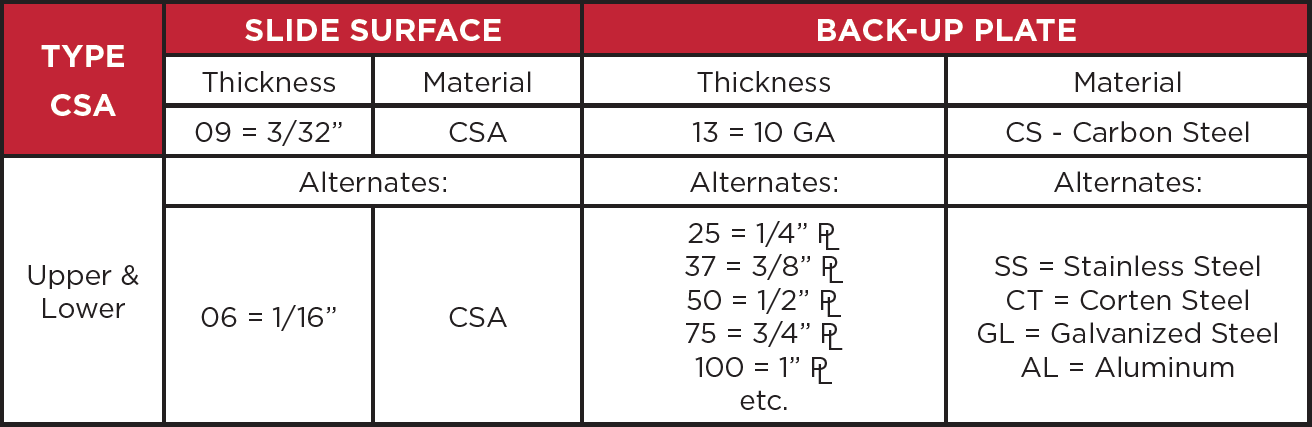

Type CSA

Upper

09CSA 13CS 50L* 9” X 9”

Lower

09CSA 13CS 50L* 8” X 8”

*09 = 3/32”, 13 = 10 GA.

Type CSB

Upper

06SS 13CS 12” X 12”

Lower

06CSB 13CS 50L* 11” X 11”

*06 = 1/16”, 13 = 10 GA.

Type CSA & CSB Technical Section

The blended CSA/CSB material used for this bearing is composed of virgin (unreprocessed) PTFE resin tested per ASTM D4894 or D4895 and reinforcing agents including milled glass fibers per ASTM D4745. This structural material has the following representative mechanical and physical properties:

Actual values per lot are available upon request which might vary due to processing factors.

- Certifications for the epoxy, steel and CSA/CSB material are available upon request.

Coefficient of Friction vs. Load

Type CSA

- Tensile Strength: 2000 psi

- Elongation: 225%

- Specific gravity: 2.17 – >2.22

Type CSB

- Tensile Strength: 3500 psi

- Elongation: 300%

- Specific gravity: 2.14 – >2.21

Coefficient of Friction

The coefficient of friction plotted is a maximum value after first movement breakaway. Friction values will rise with increased speed. The graph values will increase approximately 45% for a speed increase to 10 in./min.

The epoxy compound used by CON-SERV has been tested and formulated for bonding CSA and CSB to backing materials. The bond strength developed has a safety factor of 5 to 6 on a sliding shear, assuming no friction between the special PTFE and the back-up plate. We insure these strengths at temperatures between 300° and 500° F with a special epoxy for HT bearings (see Temperature vs. Allowable Load chart above). Some manufacturers use one epoxy for their complete temperature range, which may jeopardize bearing safety at higher temperatures.

Guidelines

Wear

Wear of CON-SLIDE™ bearings utilized in thermal expansion applications designed under the guidelines presented herein is negligible.

CON-SERV has independent laboratory tests available to certify the performance of CON-SLIDE™ bearings in cold weather. The tests were conducted per the original Alyeska Pipeline Specification. Thermal cycling from -70° F to +100° F was performed on both CSA and CSB CON-SLIDE™ bearings. They proved to perform excellently.

Ultraviolet Testing

Tests indicate that our CSA and CSB materials show no ill effects from a time-accelerated test set up. Once in place, the bearings are protected by the envelope steel on either side of the CSA or CSB material as well as shading by the structure. For further detailed information on the UV testing, consult the CON-SERV Engineering Department.

Guide Specification (Type CSA)

The following specification for CON-SLIDE™ Slide Bearings (Type CSA) will give the engineer a quality product when installed:

The bearing system, upper and lower elements, shall be CON-SLIDE™ Type CSA elements as manufactured by CON-SERV Inc., Airport Industrial Park, 685 Aviation Boulevard, Georgetown, SC, 29440, Phone: 843-546-1044.

The sliding surfaces shall be a nominal 3/32” glass-filled virgin PTFE factory-bonded with a tested epoxy to a steel back-up plate. The bonding shall be done in a heated bonding press under a controlled time, temperature and pressure. The coefficient of friction shall average .06 under a compressive load of 2000 psi. The compressive creep shall be a maximum of 2% at 2000 psi and 70° F.

The elements shall be flat, clean and prepared for installation in the structure. Slots and holes, if required, shall be fabricated in the bearing manufacturer’s plant.

Guide Specification (Type CSB)

The following specification for CON-SLIDE™ Slide Bearings (Type CSB) will give the engineer a quality product when installed:

The bearing system consists of an upper element faced with stainless steel and a lower element faced with filled PTFE, as manufactured by CON-SERV Inc., Airport Industrial Park, 685 Aviation Boulevard, Georgetown, SC, 29440, Phone: 843-546-1044. The stainless steel shall be no less than 16-gauge A240 Type 304, having a surface finish of 2B or better on the side in contact with the CSB. The stainless steel shall be TIG stitch welded or spot welded around the periphery. The CSB is a nominal 1/16” glass-filled virgin PTFE factory-bonded with a tested epoxy to a steel back-up plate. The bonding shall be done in a heated bonding press under a controlled time, temperature and pressure.

The coefficient of friction shall average .05 under a compressive load of 2000 psi. The compressive creep shall be a maximum of 2% at 2000 psi and 70° F.

The elements shall be flat, clean and prepared for installation in the structure. Slots and holes, if required, shall be fabricated in the bearing manufacturer’s plant.

Installation of CON-SLIDE™ Slide Bearings

CON-SLIDE™ bearings with PTFE flush against the edges of the steel back-up plate should be stitch welded for attachment to the structure. A fillet weld 1” long every 6” on center on each side of the element is satisfactory. Usually one tack weld on each side is sufficient for elements 6” on a side or smaller.

The recessed-PTFE type bearing can be stitch welded or seal welded. Minimize heat input into the bearing with a skip-and-fill technique for seal welding (300° F for standard bond and 500° F for HT bond).

A CON-SLIDE™ bearing set usually consists of the larger element being the upper unit over the smaller lower element, thus eliminating the possibility of accumulating dirt or contaminants on the interface. The bearing will function with a larger lower element, however. The PTFE surfaces of the bearings shall be maintained clean and free from grit, dirt or grease.

Bearing elements with slots or holes should be welded in place to ensure slot or hole location.

The bearing slide surfaces must be protected during welding and maintained clean and free from foreign matter. The surface, if PTFE, must not be exposed to direct sunlight. Keep the PTFE surfaces covered.

Remove vinyl masking from stainless steel slide surfaces before final placement in the structure. Do not scratch or mar surfaces.

Type CSA

Standard Weld Stitch Welded

Type CSB

Continuous Weld Skip and Full